Our Fiberglass Process

Why we think our works best!!!!

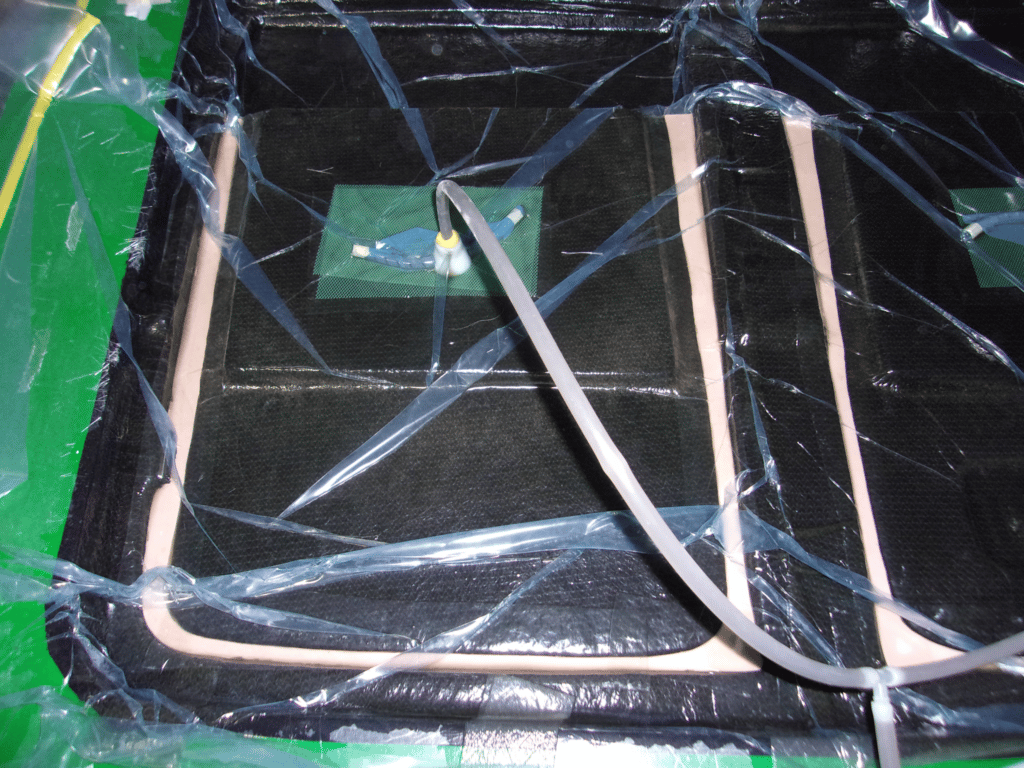

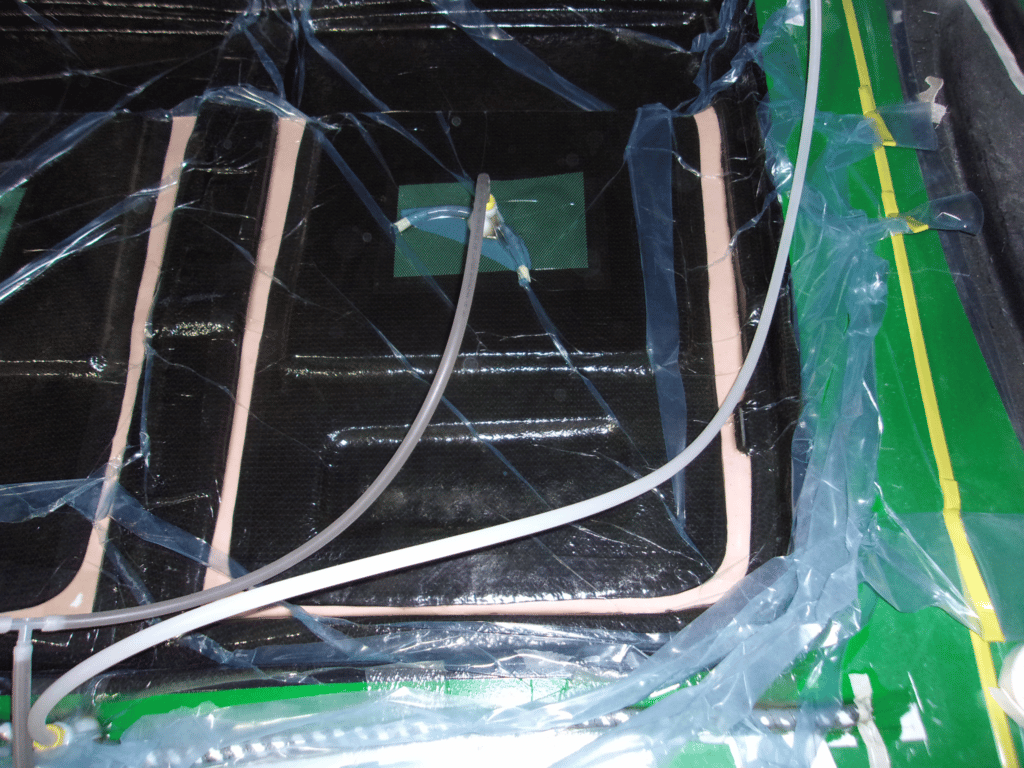

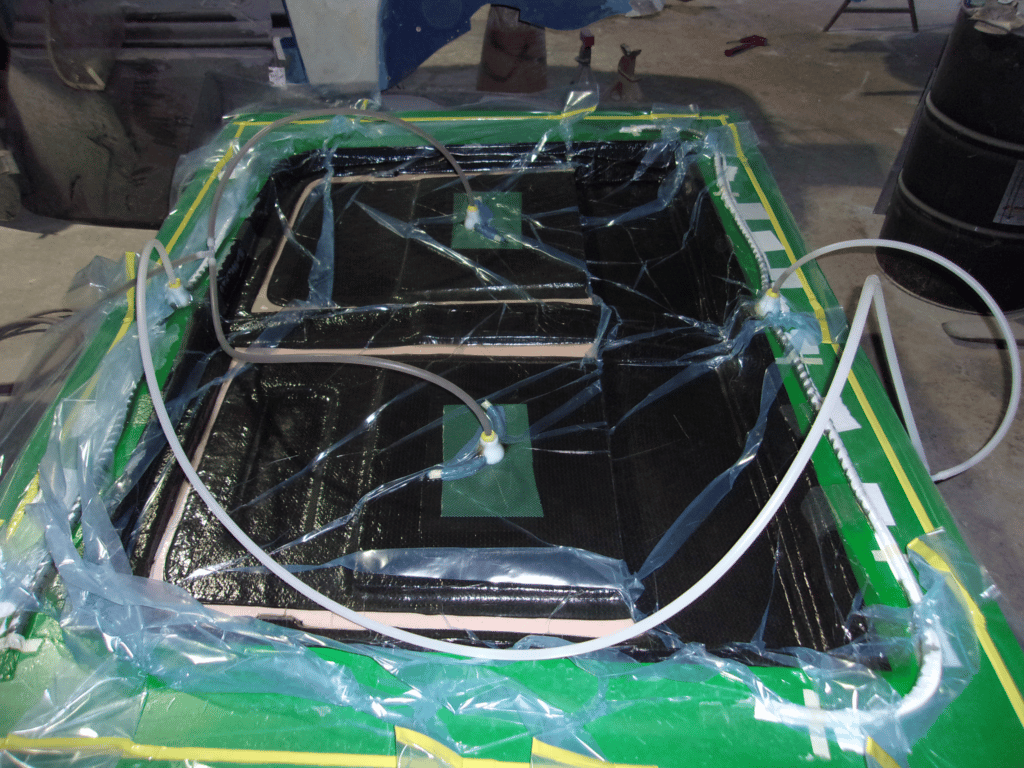

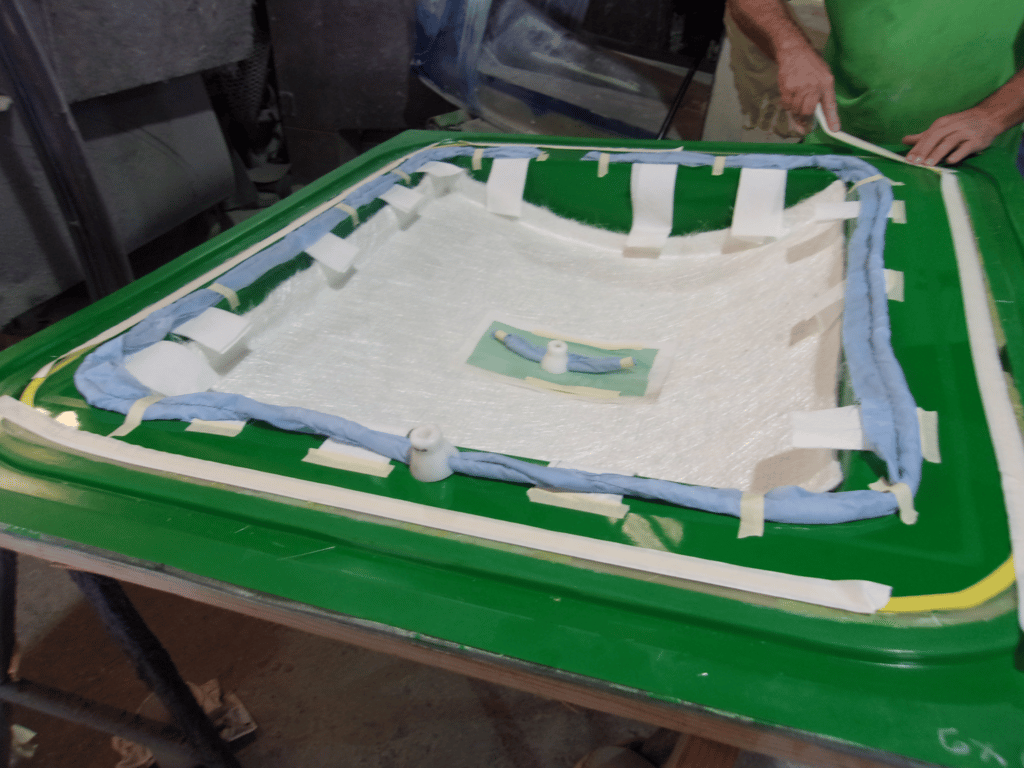

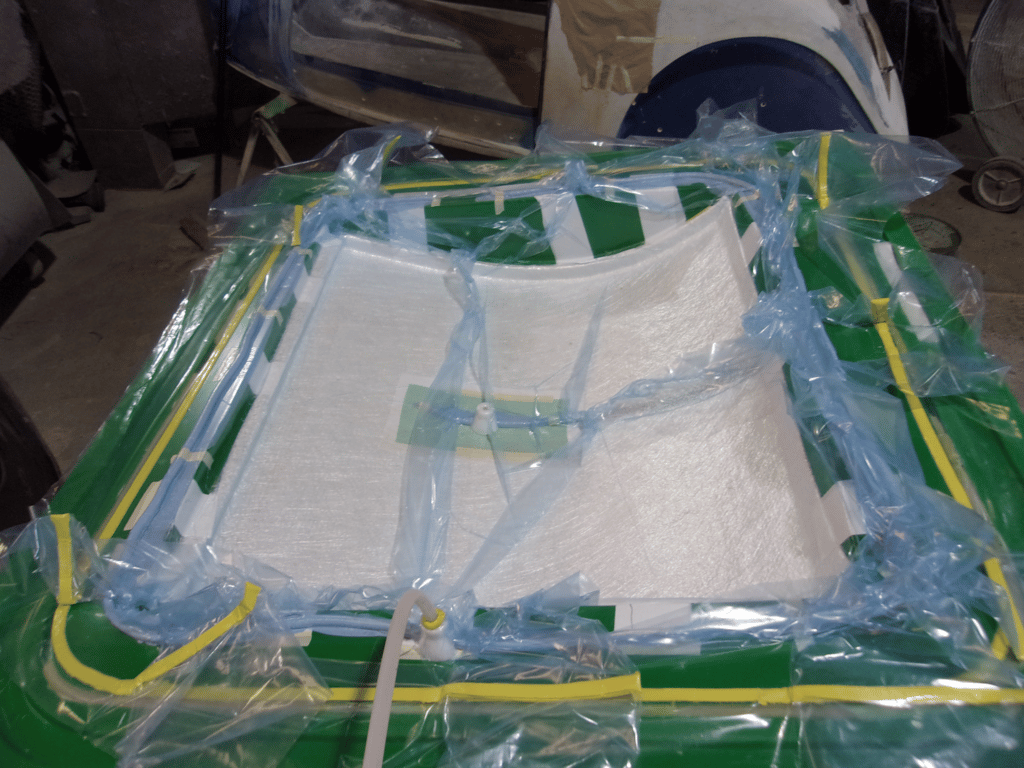

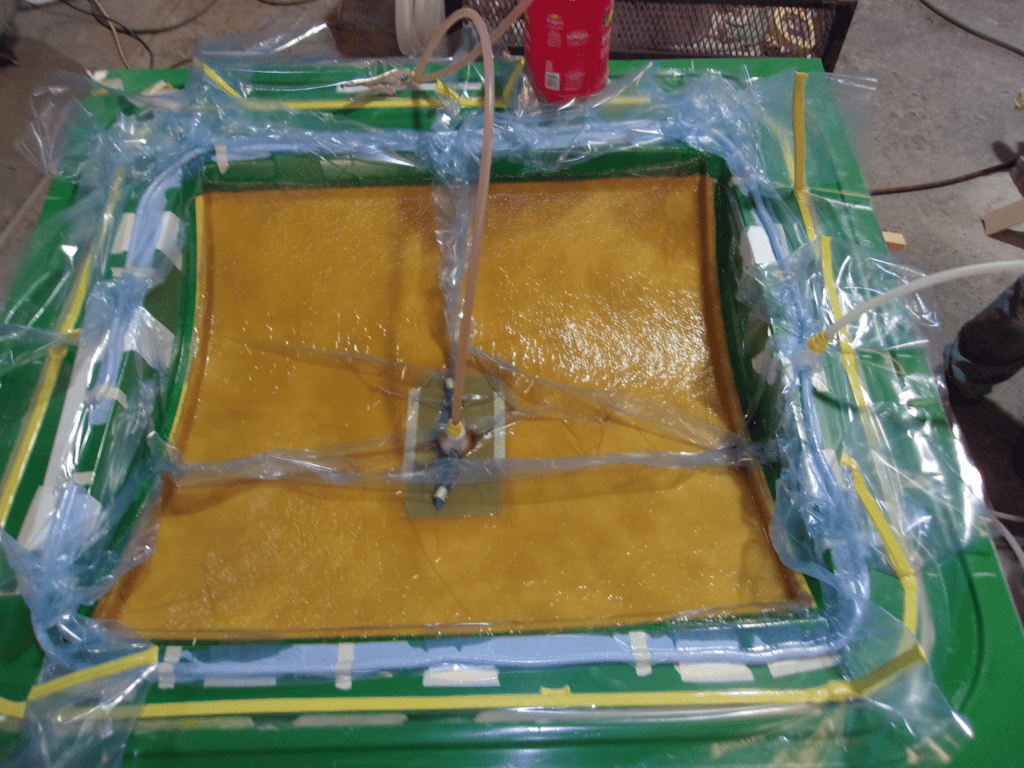

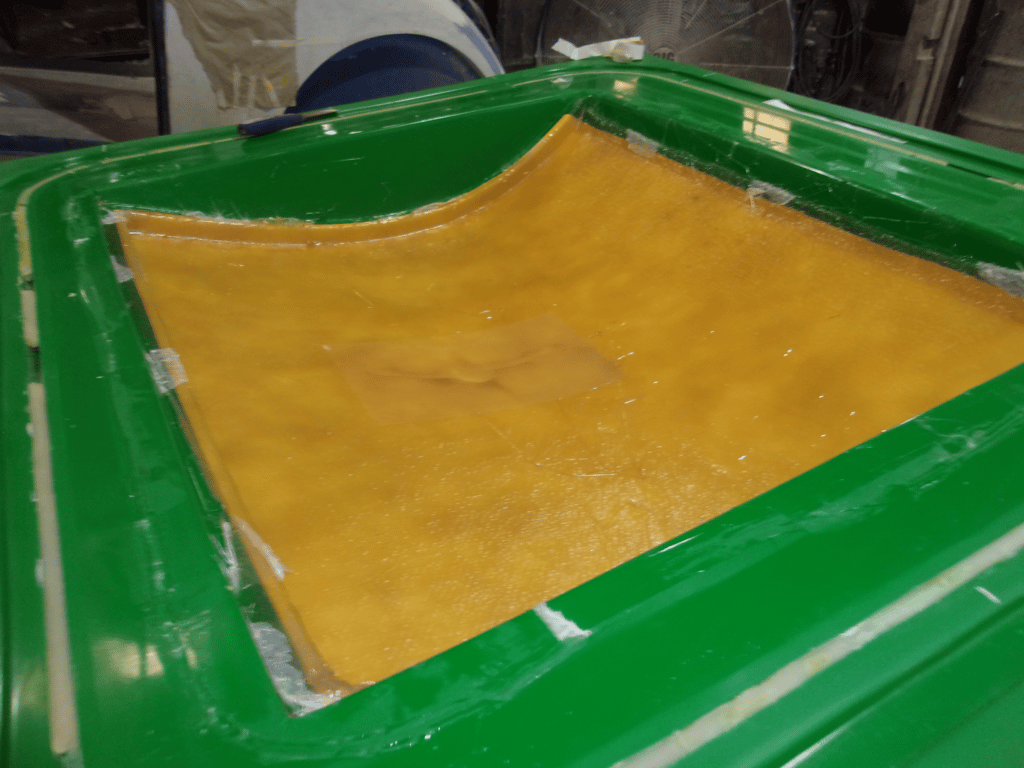

Fiberglass products that have a higher ratio of fiberglass than resin will be both lighter and stronger. We achieve this two ways. One way is using the hand lay method. The second way is thru Resin Transfer Method also known as Closed Mold / Vacuum Method. Older methods like the use of chopper guns which spray resin combined with chopped fiberglass strands typically yield products that have extremely high resin content. This yields a product that will be weaker and more brittle. While the chopper gun method may work on larger, less complex molds such as boats or tanks it has a very limited use on Hot Rod fiberglass bodies and parts.

Another important part of our process is the use of gel-coats and resins that have a high thermal deflection point. Down here in the South on a hot summer day a dark colored Hot Rod will see surface temperatures up to a 180 degrees. General purpose resins will not hold up to these temperatures.